What is a Smooth ABS Plastic Sheet and what are the characteristics of a Smooth ABS Plastic Sheet?

Jun 23, 2021|

Jun 23, 2021| View:1350

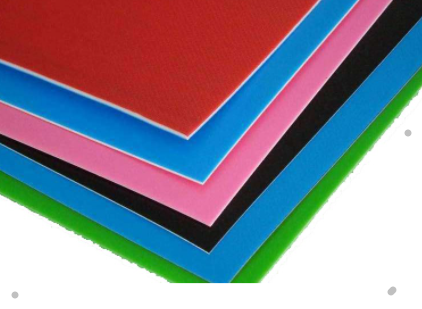

View:1350What is Smooth ABS Plastic Sheet?

Smooth ABS Plastic Sheet is an emerging material in the sheet industry, its full name is Acrylonitrile/Butadiene/Styrene copolymer sheet, which is the most produced and widely used polymer at present. It unites the various properties of PS, SAN and BS in an organic way, with excellent mechanical properties of toughness, rigidity and stiffness in balance.

Specific gravity:1.05g/cm3

Molding shrinkage:0.4-0.7%

Molding temperature:200-240℃

Drying conditions: 80-90°C 2 hours

What are the uses of Smooth ABS Plastic Sheet?

Food industry parts, architectural models, hand-made panels, components for the photovoltaic industry, the refrigerator and refrigeration industry, the electrical and electronic sector, the pharmaceutical industry, automotive parts (instrument panels, tool hatches, wheel covers, reflector cases, etc.), radio cases, telephone handles, heavy-duty tools (hoovers, hair dryers, mixers, lawn mowers, etc.), typewriter keyboards, recreational vehicles such as golf trolleys and jet skis, etc.

What are the characteristics of Smooth ABS Plastic Sheet?

1、Smooth ABS Plastic Sheet has excellent mechanical properties, its impact strength is excellent and can be used at very low temperatures; ABS has excellent wear resistance, good dimensional stability, and oil resistance, and can be used for bearings under medium loads and rotational speeds. The mechanical properties of ABS are influenced by temperature.

Smooth ABS Plastic Sheet is not affected by water, inorganic salts, alkalis and acids, but is soluble in ketones, aldehydes and chlorinated hydrocarbons, and is subject to stress cracking by ice acetic acid and vegetable oil.

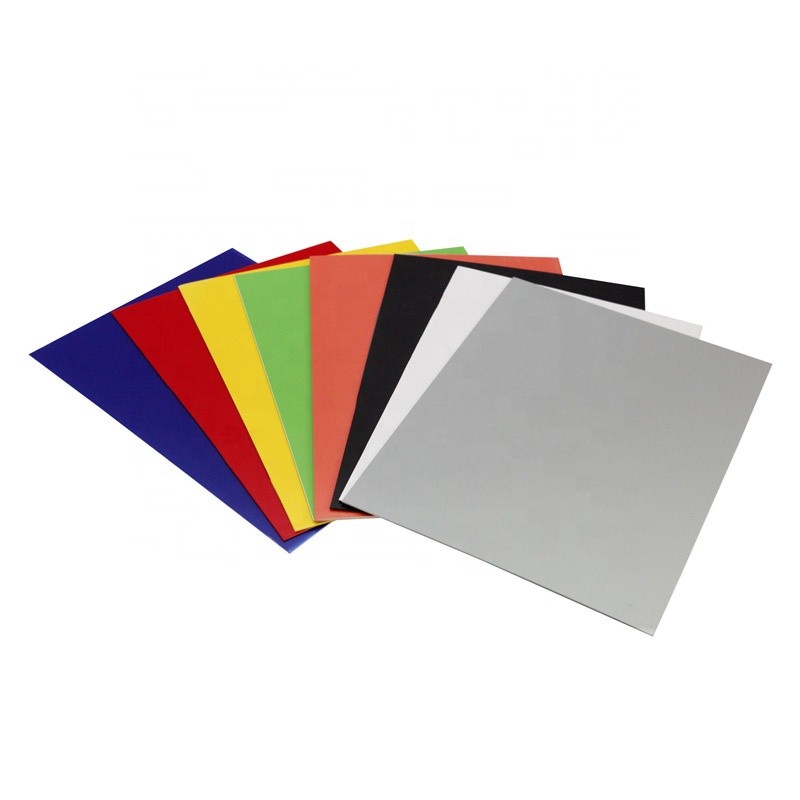

3、Smooth ABS Plastic Sheet has excellent impact strength, good dimensional stability, dyeing, good molding and mechanical processing, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, excellent chemical properties and electrical insulation properties. It can be heat resistant without deformation and also has high impact resistance toughness at low temperatures. It is also a hard, non-scratchable and non-deformable material. Low water absorption; high dimensional stability. Conventional ABS sheet is not very white, but very good toughness, can be cut by shearing machine, also can open mould punch.

4、Smooth ABS Plastic Sheet has a heat deflection temperature of 93~118℃, and the product can be increased by about 10℃ after annealing treatment. The transparent ABS sheet is very transparent and has an excellent polishing effect, making it the material of choice to replace PC sheet. Compared to acrylic, it is very tough and can be used for detailed processing of products.

Molding properties of Smooth ABS Plastic Sheet

1, amorphous material, medium fluidity, moisture absorption, must be fully dried, the surface requires glossy plastic parts must be preheated for a long time to dry 80-90 degrees.

2、High material temperature and high mould temperature are desirable, but the material temperature is too high and easy to decompose (decomposition temperature is >270 degrees). For high precision plastic parts, the mould temperature should be 50-60 degrees; for relatively high gloss and heat resistant plastic parts, the mould temperature should be 60-80 degrees.

3、If you want to solve the problem of water clamping, you need to improve the fluidity of the material, take high material temperature, high mould temperature, or change the water entry level and other methods.

4、Heat resistant or flame retardant Smooth ABS Plastic Sheet can be formed.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888