The national standard for Vacuum Forming ABS Plastic Sheet!

Jan 22, 2020|

Jan 22, 2020| View:1173

View:1173The national standard for Vacuum Forming ABS Plastic Sheet!

1. Subject content and scope of application

This standard specifies the product classification, technical requirements, test methods, inspection rules and marks, packaging, transportation and storage of acrylonitrile butadiene styrene (ABS) plastic extrusion plates (hereinafter referred to as ABS plates).

This standard is applicable to the ABS sheet made by extrusion molding with ABS resin as the base material.

This standard does not apply to embossed ABS sheets.

2. Reference standard

Gb1040: plastic tensile test method

Gb1633: Test Method for softening point (Vicat) of thermoplastic

GB1843: impact test method of a plastic cantilever beam

Gb2035: Plastic terms and definitions

Gb2918: a standard environment for conditioning and testing of plastic specimens

Gb3398: Test Method for Indentation Hardness of plastic balls

3. Product classification

3.1 product variety

Products are divided into general-purpose, high impact and heat-resistant grades according to their uses.

General-purpose: materials used for container, shell, furniture and other purposes of vacuum forming;

High impact grade: materials used for processing high impact automobile parts, street lamp signs, mechanical parts, and other purposes;

Heat resistant grade: materials used for processing motor parts and bathroom components with heat resistance requirements.

3.2 product size and deviation

3.2.1 length and width of the plate

The length and width of the plate shall be determined by the supplier and the demander through consultation

3.2.2 allowable deviation of plate length and width

When the side length of the plate l ≤ 500mm, the allowable deviation is ± 0.5%;

When the side length of the plate l > 500mm, the allowable deviation is ± 0.3%

3.2.3 the maximum diagonal difference on the same board shall not exceed 5mm

3.2.4 thickness and allowable deviation of plate

The thickness of the plate is h, 1mm, 10 mm;

The allowable deviation of plate thickness is (± 0.05 + 0.03h) mm,

3.3 colors

Generally, it is a natural color. Other colors can be determined by both parties through negotiation.

4. Technical requirements

4.1 appearance

The surface of the plate shall be smooth and flat, and there shall be no ripple, shortage mark, scratch, black spot and impurity affecting the use; there shall be no bubble and crack. If there are special requirements for appearance, they shall be agreed upon by both parties.

4.2 the size and deviation of plates shall comply with the provisions of Article 3.2 of this standard.

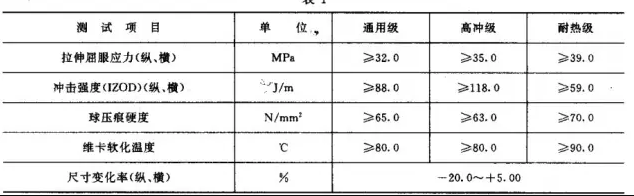

4.3 technical performance index

The technical performance index shall meet the requirements of Table 1.

Note: the technical performance indexes of vacuum forming ABS plastic sheet for refrigerator shall be assessed according to the grade of raw materials used and the user's needs and the corresponding high impact or general level indexes.

5. Test method

5.1 test conditions

The samples were placed at 23 ± 2'c and relative humidity of 45-55% for more than 16 hours and tested under the same conditions.

5.2 appearance

It is 50cm away from the plate, and the appearance quality is observed vertically with the naked eye under the natural light.

5.3 measurement of dimensions

5.3.1 determination of length, width and diagonal

The length, width and diagonal of the plate are measured with a measuring tool with an accuracy of 1mm. The length and width shall be measured at three points at equal intervals on both sides, and the maximum value, minimum value, and arithmetic mean value shall be recorded; the distance between the two opposite ends of the same plate shall be measured by diagonal, and the difference between the two diagonal lines shall be calculated, which shall meet the requirements of 3.2.

5.3.2 determination of thickness

The thickness of the plate shall be accurate too. 02mm measuring tool, the measuring point at the end shall be 10 mm away from the edge of the plate. One point shall be measured every 20cm in the length direction and every 10cm in the width direction. The maximum value, minimum value and arithmetic mean value shall be recorded, which shall meet the requirements of Article 3.2.

5.4 determination of tensile yield stress

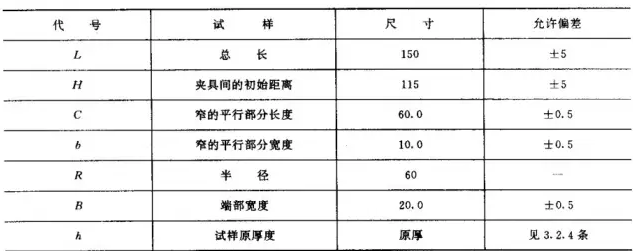

5.4.1 sample

5.4.1.1 see Table 2 for sample shape and size

5.4.1.2 at least 5 shape samples shall be processed in the longitudinal and transverse directions of the sample by machining.

5.4.2 test speed

The test speed is 20 mm / min,

5.4.3 test equipment and steps

According to gb1040.

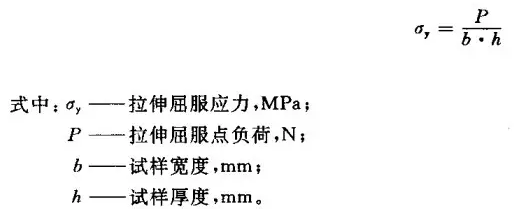

5.4.4 calculation and representation of test results

The test results are represented by the arithmetic mean and three significant figures are taken.

5.5 determination of impact strength

According to GB1843.

If the thickness of the sample is less than 3mm, stack the sample to a thickness greater than 3mm, align the two ends of the sample notch, and tie it with transparent tape for the test, with a maximum of three layers stacked.

The test results are represented by the arithmetic mean and three significant figures are taken.

5.6 Vicat softening temperature measurement

According to gb1633. The test load is 49n and the constant heating rate is 50 ` C / h. The test results are represented by the arithmetic mean and three significant figures are taken.

5.7 determination of ball indentation hardness

According to gb3398. The test load is 358n, and the test result is represented by arithmetic mean value, taking three significant figures.

6. Inspection rules

6.1 batches of batches

ABS plates are produced in one batch with the same brand, formula, process, and color. The quantity of each batch shall not exceed 10 tons. A single delivery may consist of one or more batches. Batch number shall be indicated at the time of delivery. Products of the same delivery batch number are one delivery inspection batch.

6.2 sampling inspection plan

6.2 during the door acceptance inspection, the external packaging of the product shall be checked first, and sufficient packaging units shall be randomly selected from the intact packaging products. If the intact packaging quantity is less than half of the total packaging quantity of the delivered batch, the acceptance inspection shall not be carried out, which shall be solved by the supplier and the demander through consultation.

6.2.2 appearance, dimension, and deviation, batch quality level (PO) is 6.5% 0

6.2.3 the sample unit is composed of packages. According to table 4, samples shall be taken from the delivery inspection lot, and then anyone plate shall be taken from each package of samples. For the inspection of technical performance, five samples shall be randomly cut from the samples taken in the longitudinal and transverse directions according to the provisions of this standard for test.

6.3 type inspection

Carry out all performance tests on 3.2 and Chapter 4. Generally at least once a quarter. Type inspection shall be carried out in case of any of the following conditions.

a. Trial production and finalization appraisal of new products or old products transferred to other factories;

b. After formal production, if the structure, material, and process are greatly changed, which may affect product performance;

c. After the product is stopped for a long time, the production is resumed;

d. When there is a big difference between the delivery inspection result and the last type inspection;

e. When the national quality supervision agency puts forward the requirements for type inspection.

6.4 delivery inspection

Product size and deviation shall be inspected as per article 3.2; appearance shall be inspected as per Article 4.1; technical performance shall be inspected as per article 4.3 only for impact strength and tensile yield stress.

7. Marking, packaging, transportation, and storage

7.1 mark

The product package has the following marks:

a. Name of the manufacturer;

b. Product name and quantity;

c. trademark;

d. Product model (specification) or mark;

e. Manufacturing date or batch number;

f. Quality level mark.

7.2 packaging

Each package is generally no more than 30kg, packed with plastic film or moisture-proof paper, and bound firmly.

7.3 transport

During transportation, the Board shall be protected from rain, sun exposure, contamination, heavy pressure, and damage.

7.4 storage

The plate shall be kept in a dry warehouse away from the heat source, and the storage period shall not exceed one year from the date of production.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888