Features and Application Benefits of Smooth ABS Plastic Sheet

May 10, 2021|

May 10, 2021| View:1047

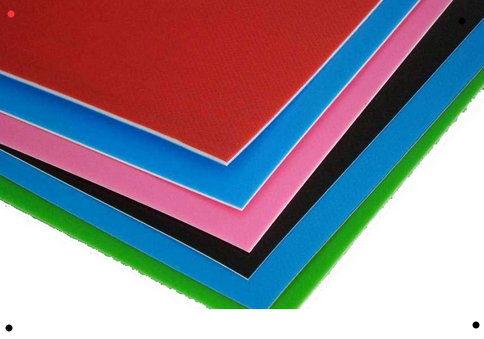

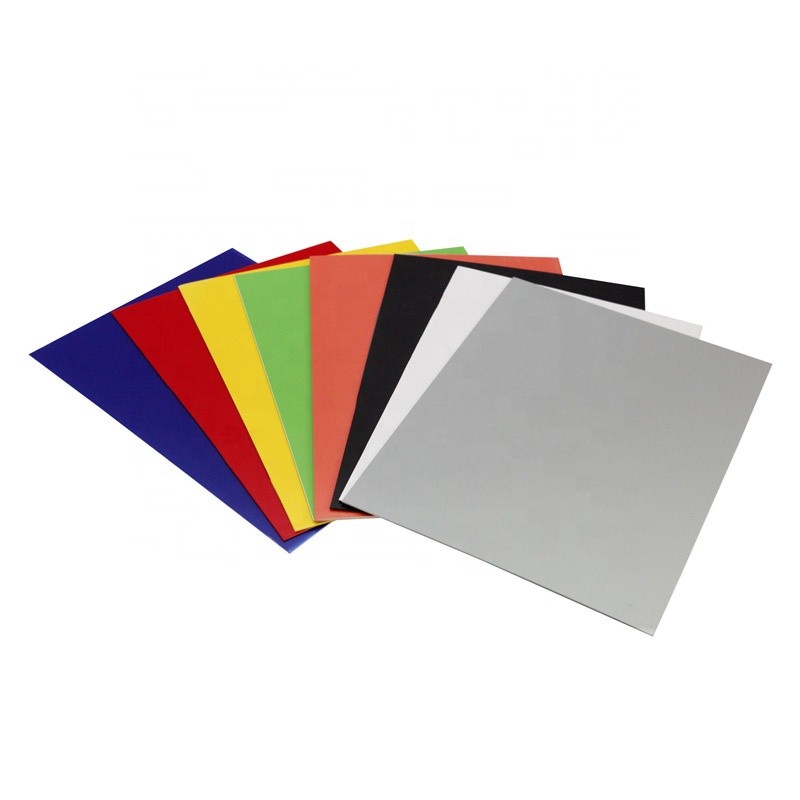

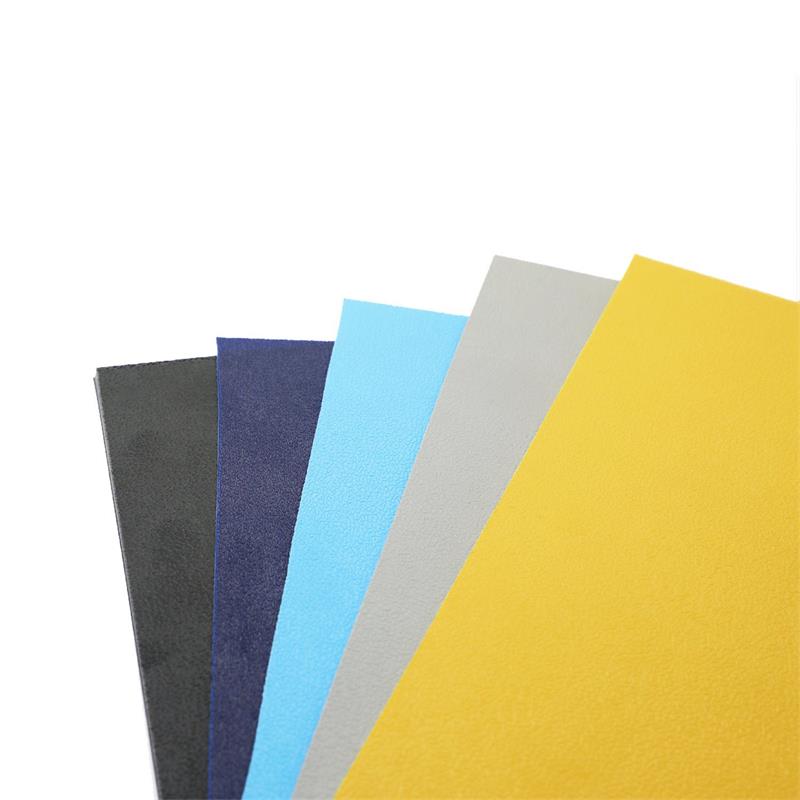

View:1047Smooth ABS Plastic Sheet is an emerging material in the sheet industry. Its full name is acrylonitrile/butadiene/styrene copolymer sheet, and it is the most widely used polymer with the largest production volume. It organically unifies the various properties of PS, SAN, and BS, and has excellent mechanical properties of toughness, rigidity, and stiffness in balance.

ABS has excellent mechanical properties, its impact strength is excellent and can be used at very low temperatures; ABS has excellent wear resistance, good dimensional stability, and oil resistance, and can be used for bearings under medium load and speed. The mechanical properties of ABS are affected by temperature.

. ABS is not affected by water, inorganic salts, alkalis and acids, but is soluble in ketones, aldehydes and chlorinated hydrocarbons, and is subject to stress cracking by ice acetic acid and vegetable oil.

3. Excellent impact strength, good dimensional stability, dyeing, good molding and machining, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, excellent chemical properties and electrical insulation properties. It can be heat resistant without deformation, and also has high impact resistance toughness in low temperature conditions. Still a hard, not easy to scratch, not easy to deformation of the material. Low water absorption; high dimensional stability. Conventional ABS sheet is not very white, but very good toughness, can be cut with shears, but also can open the mold punch.

4. low temperature resistance, ABS sheet heat deformation temperature of 93 ~ 118 ℃, the product can also be increased by about 10 ℃ after annealing treatment. ABS can still show a certain degree of toughness at -40 ℃, can be used in the temperature range of -40 ~ 100 ℃. Among them, transparent ABS sheet has very good transparency and excellent grinding and polishing effect, which is the preferred material to replace PC sheet. Compared with acrylic, it is very good toughness, can meet the detailed processing of products.

5. Good overall performance, high impact strength, chemical stability, good electrical properties.

6. Good fusion with PMMA, make two-color plastic parts, and the surface can be chrome-plated, paint treatment.

7. There are high impact resistance, high heat resistance, flame retardant, reinforced, transparent and other levels.

8. Liquidity is a little worse than HIPS, better than PMMA, PC, etc., good flexibility.

9. There are also flame-resistant ABS plastic sheets, which are mainly used for information industry materials, such as computer housings, modems, monitor housings, etc.

Applications of Smooth ABS Plastic Sheet:

Smooth ABS Plastic Sheet can be used as the shell and internal components of TV, radio, washing machine, refrigerator, telephone, air conditioner and other electrical appliances.

2.Auto parts. Smooth ABS Plastic Sheet is used to make auto parts, such as shell, adjusting handle, door lining, control switch knob, conduit, etc. ABS is mainly used for impact resistance, such as strength, stiffness and formability. Accessories are fenders, armrests, ventilation covers, supports, cushion extension plates, etc.

3. Office equipment. The use of ABS sheet excellent impact resistance, excellent rigidity, dimensional stability and formability, for the manufacture of a variety of office equipment shell both economic and practical. Such as fax machines, copiers, typewriters and computer monitors and other office equipment, fire resistance requirements are higher, so the general flame retardant ABS for the order of merit.

4. mechanical ABS plastic shell can be produced mechanical equipment and general mechanical parts used. Such as water tanks, electrical cabinet shells, battery cans, gear bearings, pump impeller mold models and fasteners, bolts, covers.

5. Mold model. Due to the superior processing performance, light weight and low price of Smooth ABS Plastic Sheet material, it has been widely used in recent years for manufacturing mold models for home appliances industry, automobiles, machinery and equipment, testing instruments. Currently the world leader in the use of ABS as a standard material for the production of three-dimensional prototypes, then you can do anything you want to test the appearance of the new product modeling, suitability and related functions of the model flyer size machine. It has the best cost performance in its class.

ABS sheet production process can be divided into upstream and downstream processes. Upstream process refers to melting, casting, hot rolling, cold rolling, etc., which are the same as those of other high precision sheets and strips. The downstream process refers to heat treatment, surface treatment, drawing, bending and straightening, lubricant coating, longitudinal and transverse shearing, precision cutting and deep processing, etc. Its downstream process is much more complicated and has more processes than other high-precision sheets. It can be briefly expressed as: uncoiling - heat treatment, air cushion furnace (available fuel, electricity or induction heating) solution treatment (temperature 500 ~ 600 ℃) or annealing, water quenching / air quenching - surface treatment (cleaning and transformation treatment) - bending sedan - lubricant coating - coiling, etc.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888