What problems need attention when processing acrylic sheet?

Feb 05, 2021|

Feb 05, 2021| View:692

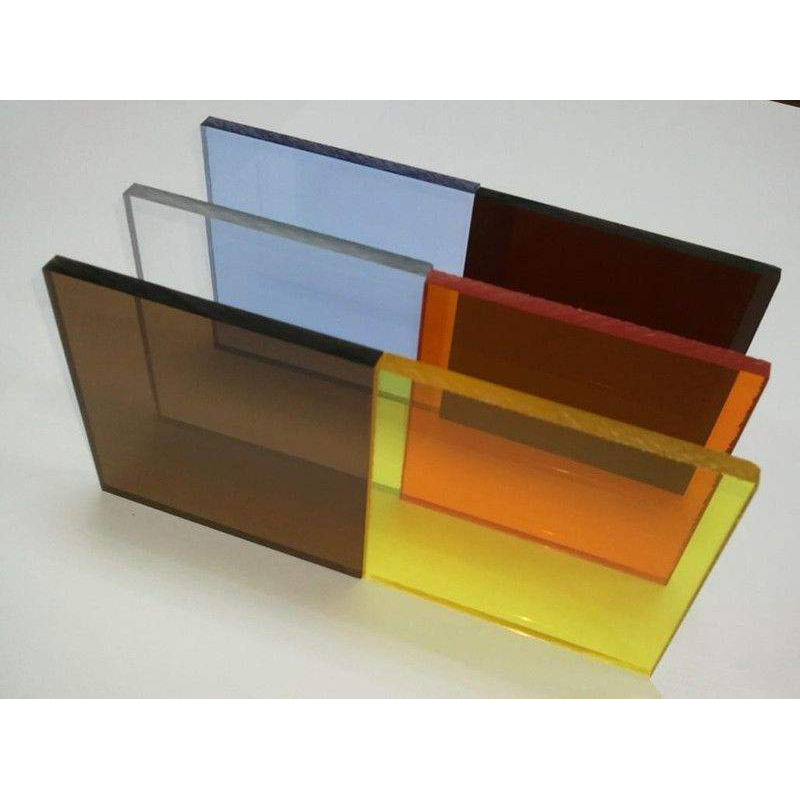

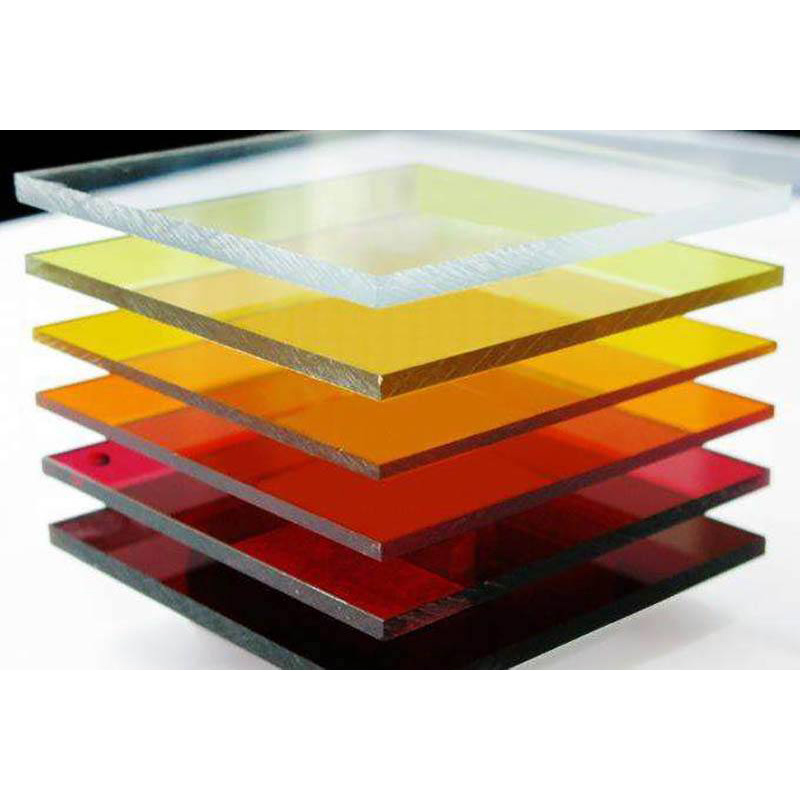

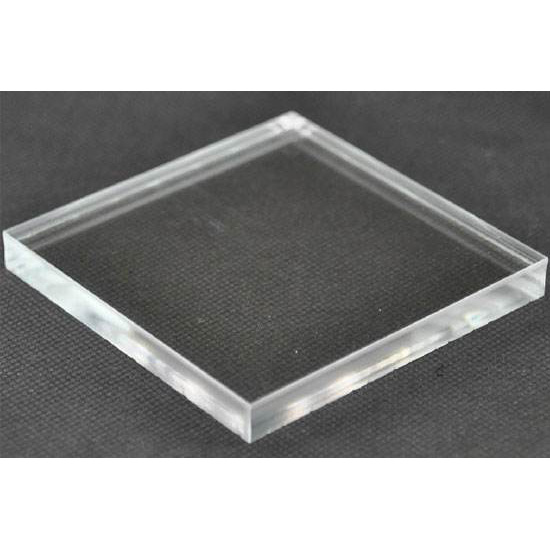

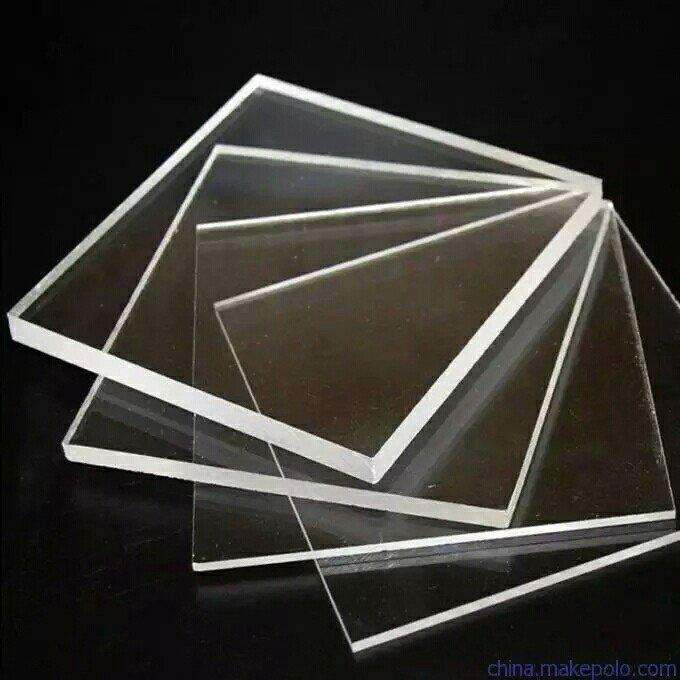

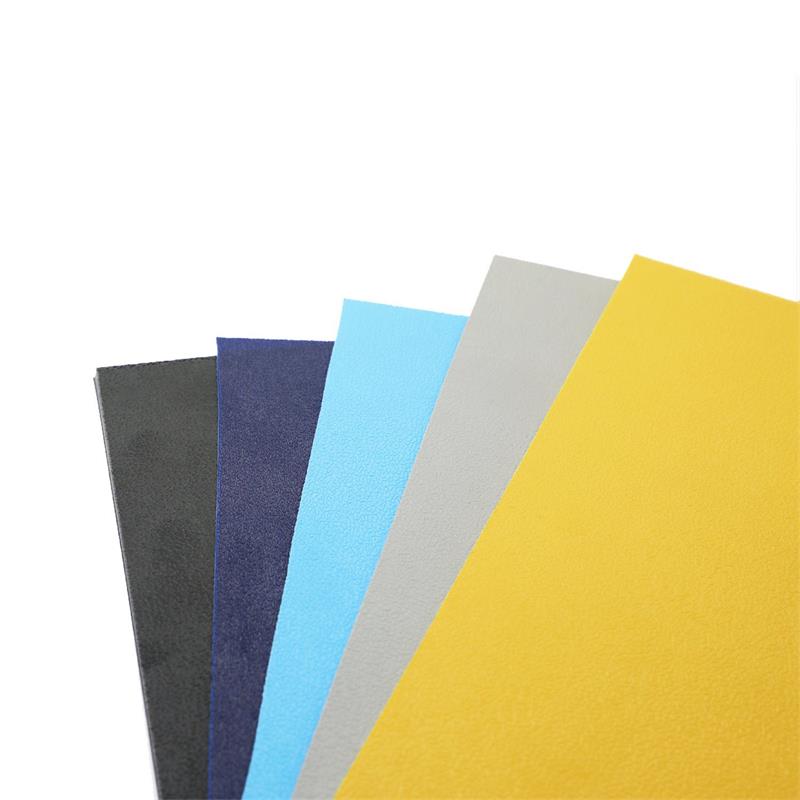

View:692Acrylic, organic glass, derived from acrylic (acrylic plastic), with good transparency, chemical stability and weather resistance, easy dyeing, easy processing, beautiful appearance, has a wide range of applications in the construction industry.

Acrylic is often made into signs, corporate culture display boards, etc. Acrylic is a good plane material, printing on acrylic can print out concave and convex feeling, feel hierarchical, more visual effect.

01

Storage method of acrylic

Acrylic is widely used, but in the process of transportation and storage, we should pay attention to the following matters:

1. Acrylic board should not be stored in the same place with other organic solvents, let alone in contact with organic solvents.

2. During transportation, the surface protective film or protective paper shall not be abraded. (because of the high permeability of acrylic, it is easy to produce scratches, and if there is more friction with the outside world, the scratches will be more obvious).

3. It can not be used in the environment with temperature over 85 ℃. (acrylic softens easily in high temperature)

4. In daily cleaning, wipe it with a wet towel or newspaper. In case of stains, wipe it with a towel dipped in beer or warm vinegar. In addition, you can also use the glass cleaning agent currently on the market. Do not use the solution with strong acidity and alkalinity. In winter, acrylic products are easy to frosting, and can be cleaned with cloth or salt baijiu.

5. The coefficient of thermal expansion of acrylic plate is very large, so the expansion gap should be reserved due to the temperature change.

02

Acrylic correction method

If it is just found unsatisfactory printing, you can spray alcohol, after a while, you can wipe it off gently;

More than 12 hours can be soaked in alcohol, 30 minutes can be torn off (can also be soaked in warm water, the time is relatively long);

If it is more than 24 hours, you can use hydrogen peroxide, banana water cleaning.

03

What should be paid attention to when making acrylic

When the UV printer is running, you cannot turn off the UV printer or unplug the power. UV printing belongs to digital printing, which is controlled by computer. If the power is turned off, the printing will be interrupted.

Acrylic surface is smooth. If there is dust in the air of UV printing environment, it is easy to accumulate on the material surface, causing the pattern to be white and other colors to be omitted.

When UV printing, the height between the nozzle and acrylic should be suitable, too high or too low from the nozzle to acrylic will cause the printing image blurring or ghosting.

Acrylic should spray coating on the printing surface before UV printing, because the surface of acrylic is relatively smooth, and it is easy to scrape the UV printing image directly on it. After spraying the coating, it can make the UV pigment adhere to it better, and it is not easy to scrape off.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888