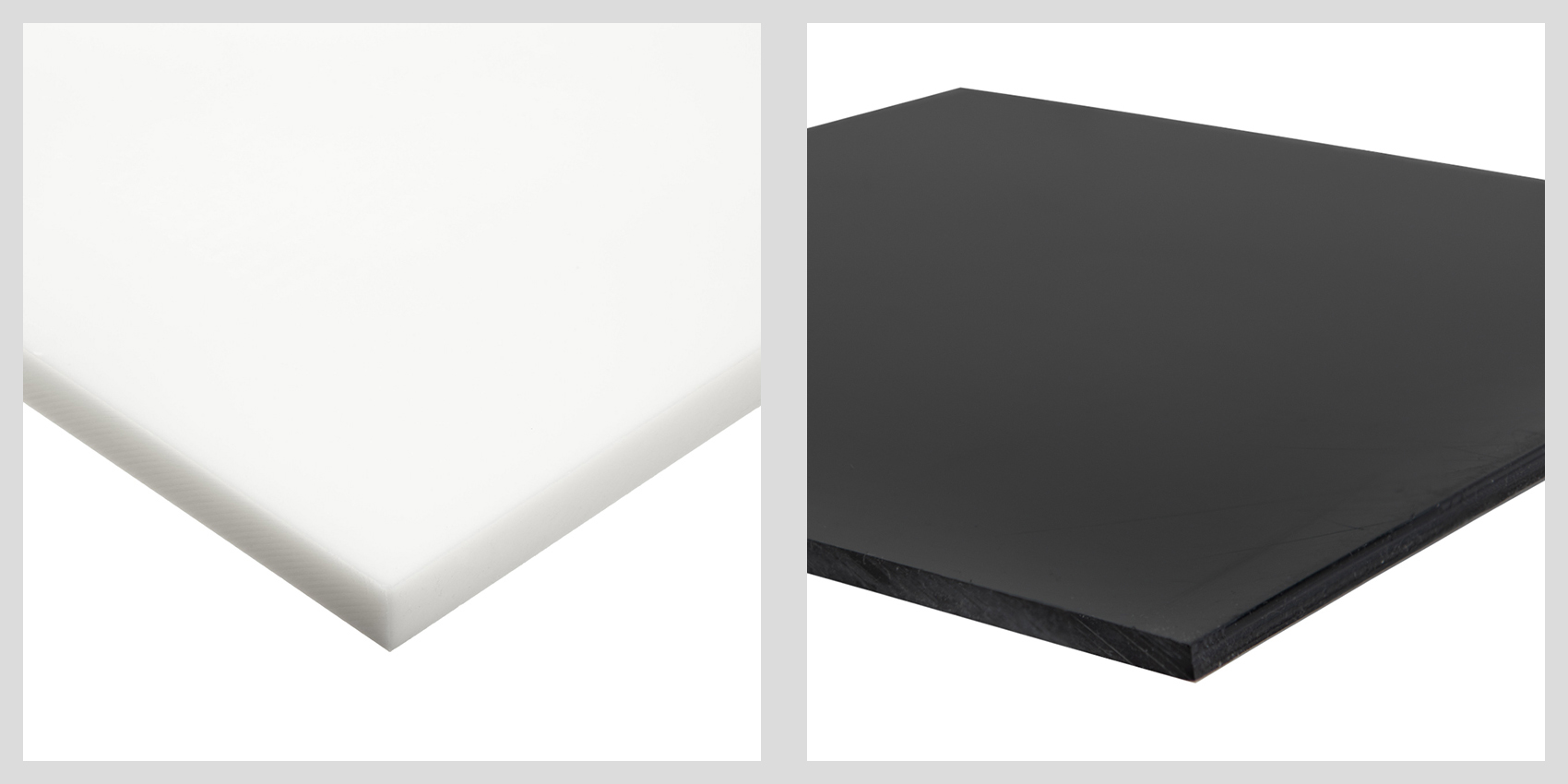

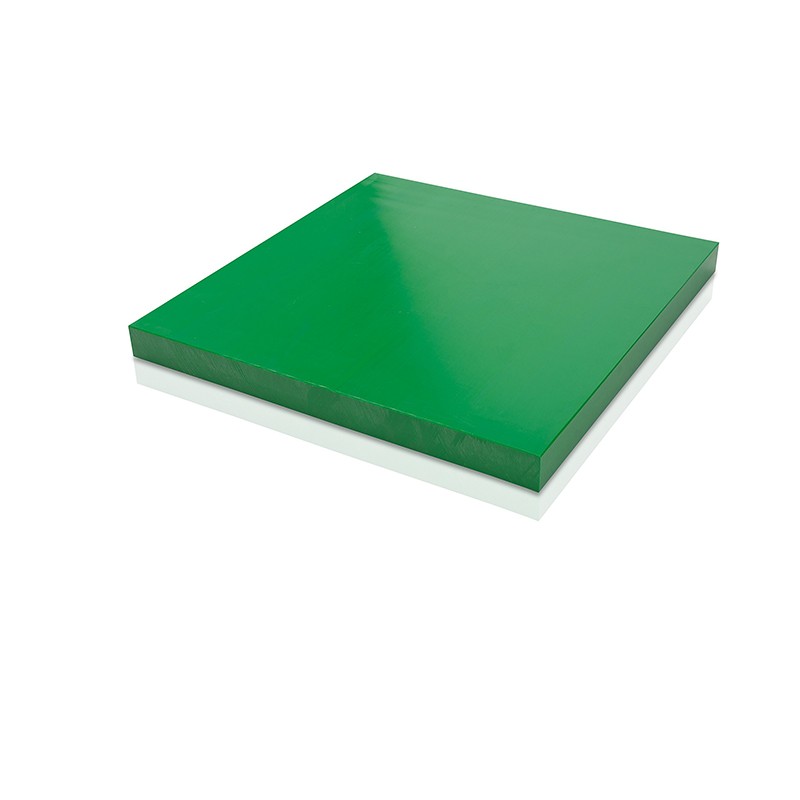

HDPE Plastic Sheet

HDPE sheet

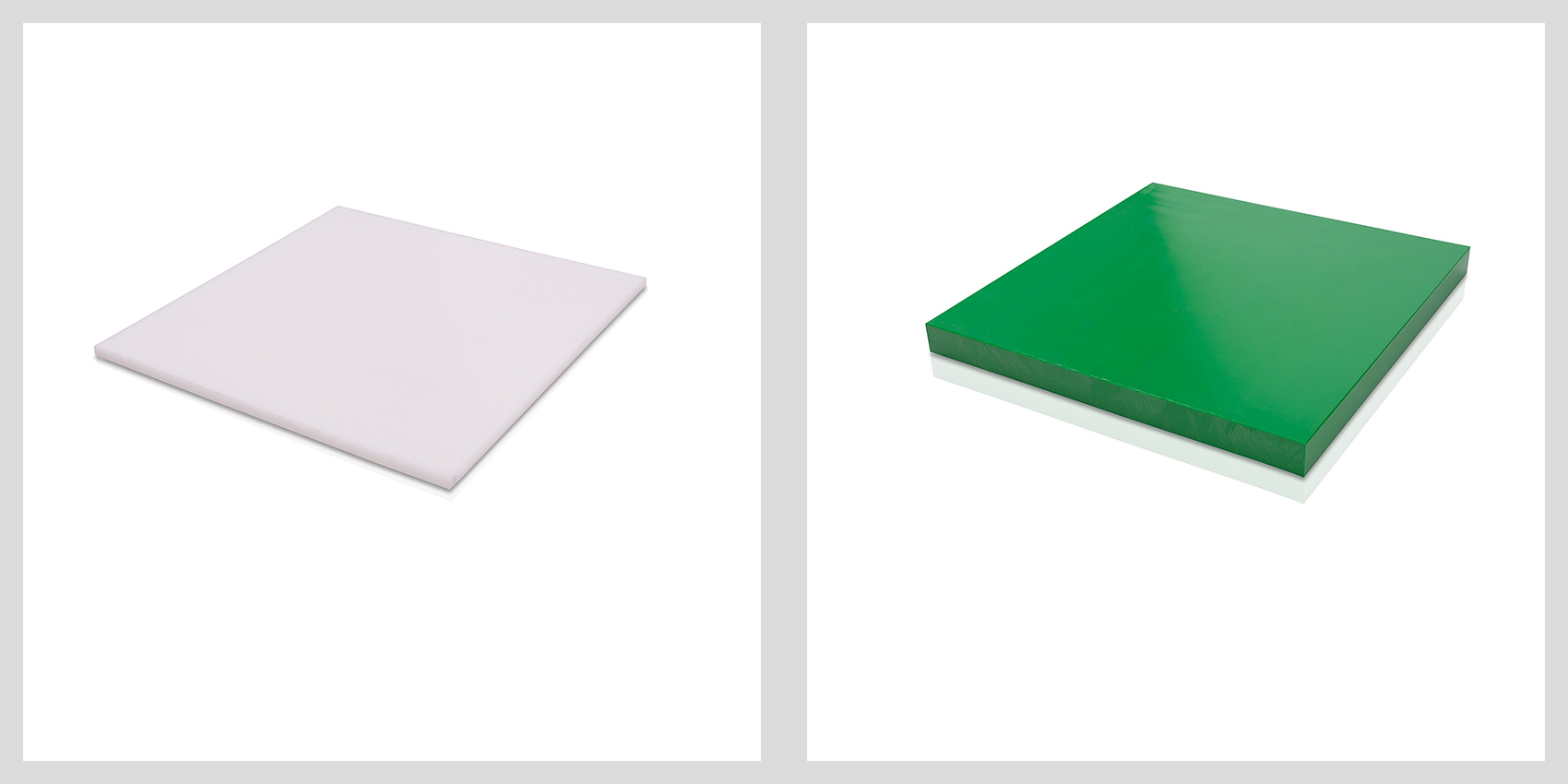

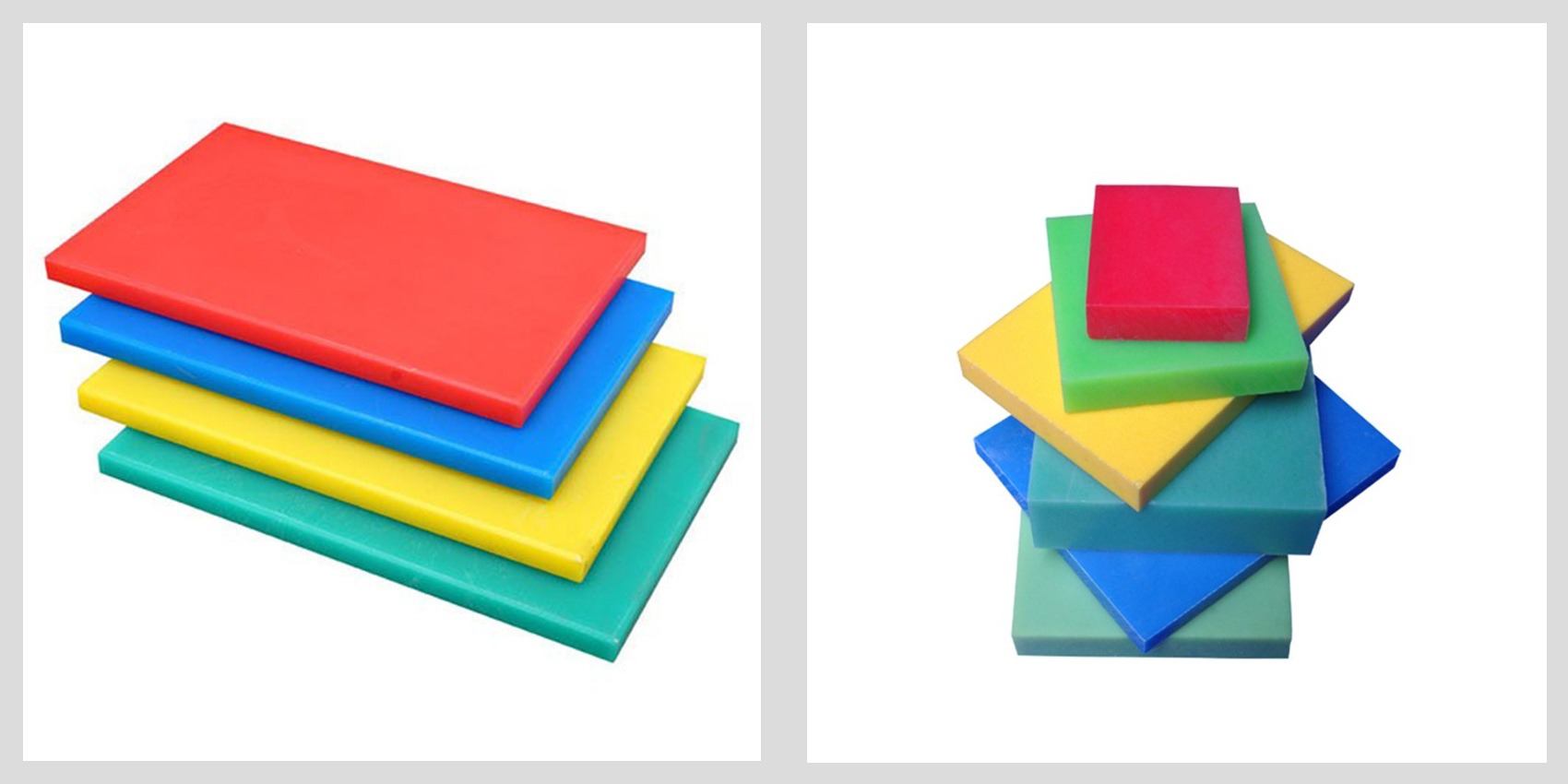

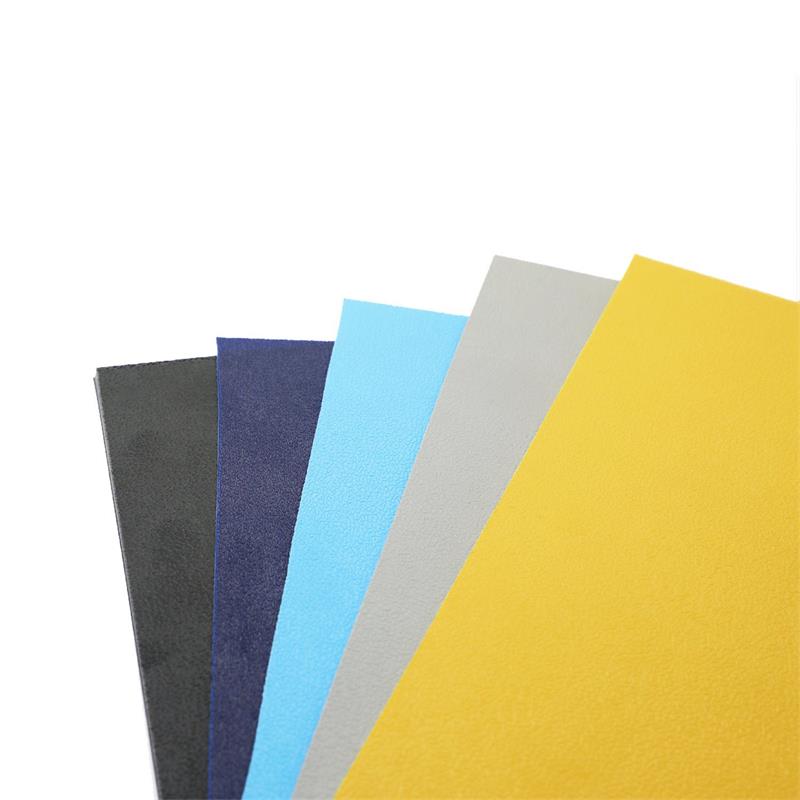

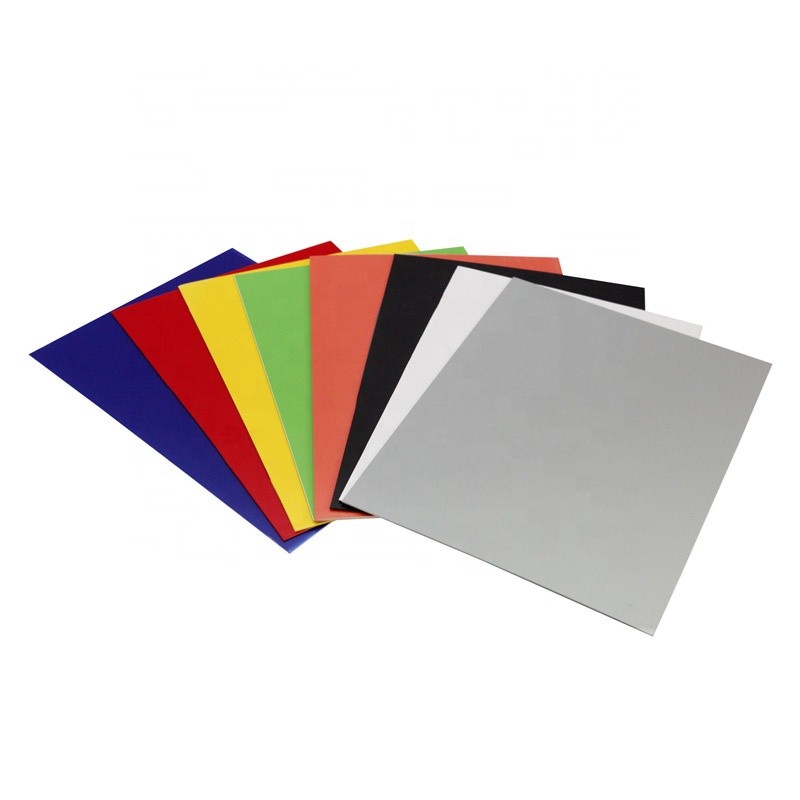

Color: Customizable

Material: High-density polyethylene

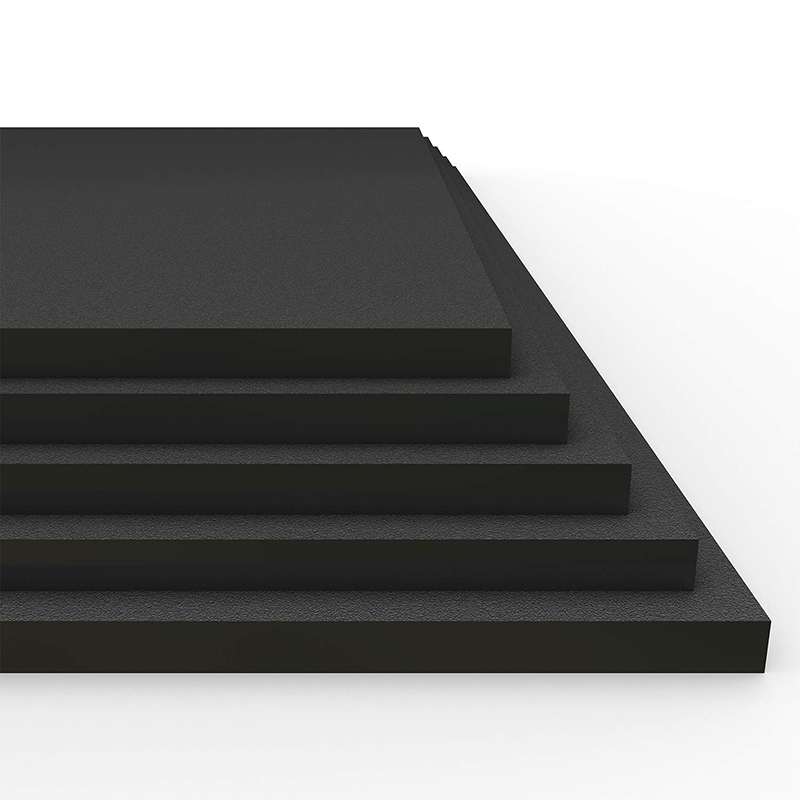

Thickness: 0.35mm-9mm

Max Width: 800mm-1900mm

Sample: A4 size

MOQ: 2 tons

Application: Food industry and water industry

Color: Customizable

Material: High-density polyethylene

Thickness: 0.35mm-9mm

Max Width: 800mm-1900mm

Sample: A4 size

MOQ: 2 tons

Application: Food industry and water industry

Product Introduction

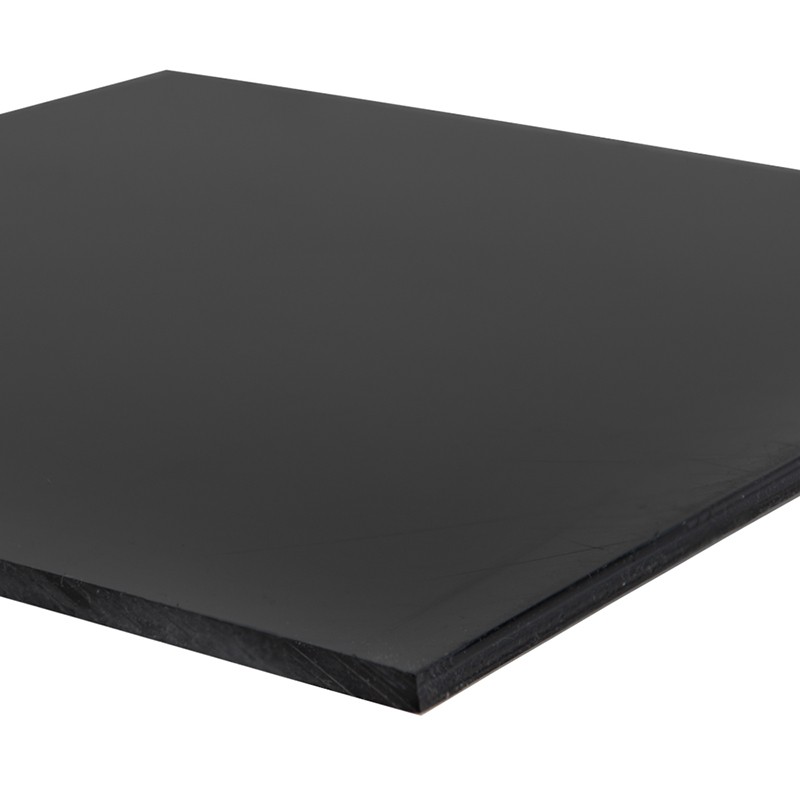

High density polyethylene plastic is most commonly known and referred to as HDPE sheet plastic. This thermoplastic is made from a string of ethylene molecules (hence, the poly part of polyethylene), and is known for being both lightweight and strong. With more and more companies embracing sustainability initiatives, HDPE sheet popularity has skyrocketed as it can cut down on the material used to produce and package products due to its weight and strength.

1. Cost-effective

2. Can withstand temperatures from -148 to 176 degrees Fahrenheit

3. Non-leaching

4. UV-resistant

5. Dishwasher safe

6. Resistant to most chemical solvents

7. Stiff material

Product Details

Inquiry Now

Keywords

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888