- CHANGZHOU SUNPLAS is a reputable company renowned for its expertise in manufacturing and supplying high-quality 0.6mm ABS plastic sheets. These sheets are widely used in various industries due to thei...

07 Apr

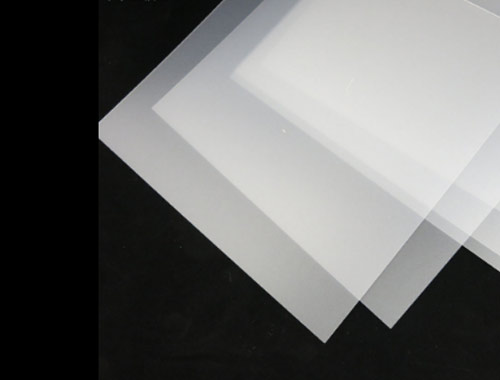

- PS diffuser sheets are versatile materials that offer numerous advantages for lighting applications. These sheets are specifically designed to enhance the uniformity of light distribution, reduce glar...

18 Nov

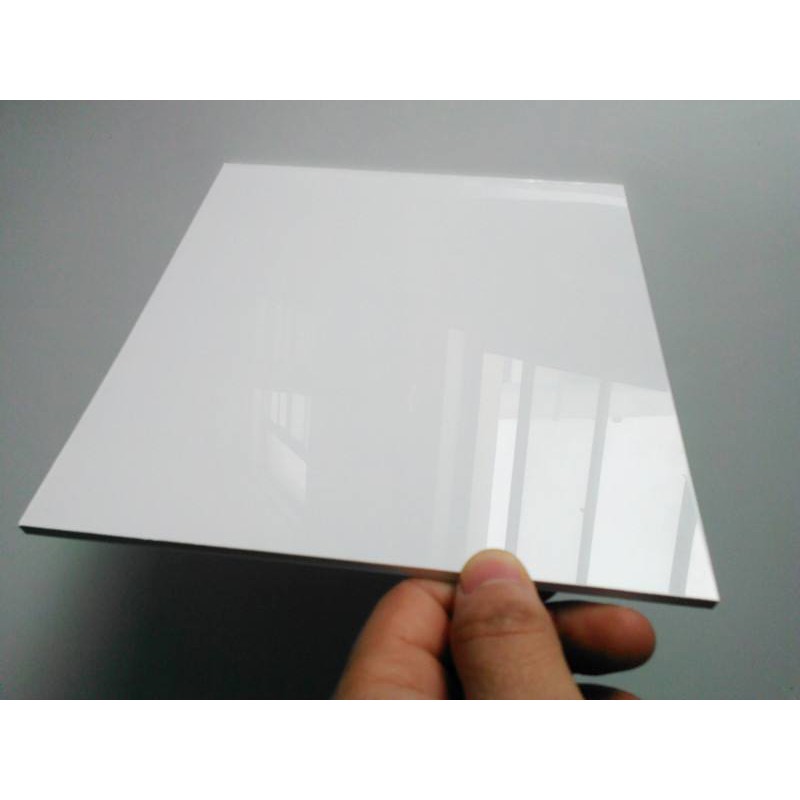

- In the age of innovation, materials that offer both protection and enhancement are highly sought after. UV plastic sheets have emerged as versatile solutions that not only shield against harmful ultra...

26 Aug

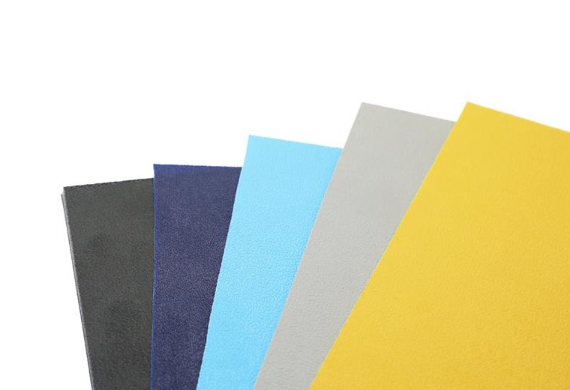

- Smooth ABS (Acrylonitrile Butadiene Styrene) plastic sheets are a versatile and widely used material in various industries due to their exceptional properties and benefits. ABS is a thermoplastic know...

27 Jul

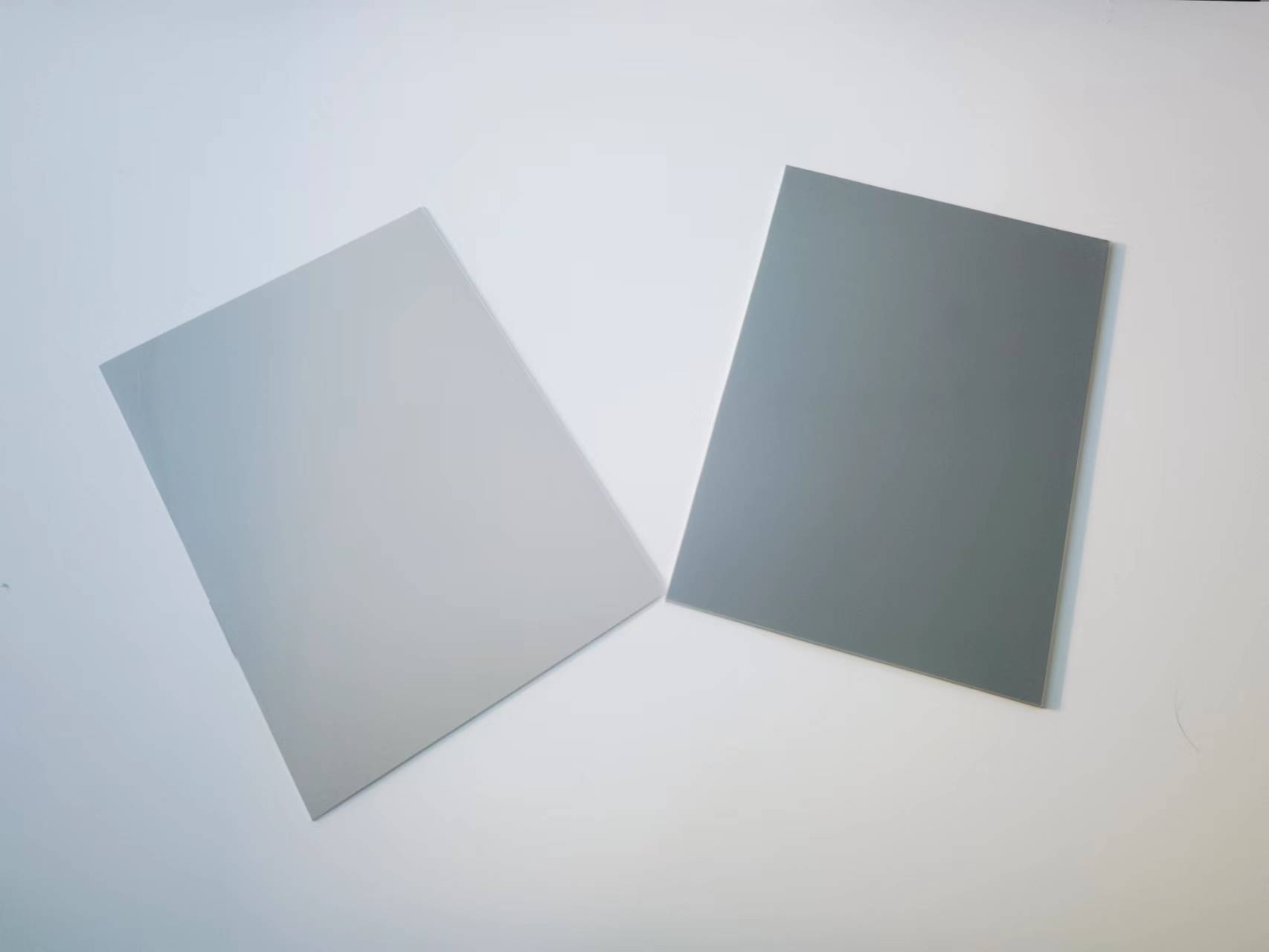

- HIPS Sheet, also known as high impact polystyrene sheet, is a plastic sheet made from polymer HIPS.

18 May

- High Impact Styrene Sheet is a versatile and cost-effective material that has gained popularity in a variety of industries, including the sign industry.

27 Apr

- PS Diffusion sheet has become an essential element in both photography and filmmaking.

30 Mar

- Polystyrene (PS) is one of the world's most popular thermoplastic materials, but depending on your application, you will need to use either HIPS Sheet or GPPS Sheet.

02 Mar

- Before understanding the end consumption of the PS Diffusion sheet, there is a topic that cannot be avoided: the substitution relationship between the PS Diffusion sheet and the ABS sheet.

19 Jan

- With the development of society, automobiles are becoming more and more common. The current flame-retardant polymer materials used in automotive parts are mainly ABS Plastic Boards which are environme...

22 Dec

- With the development of science and technology, many new and better materials have been developed, and ABS Plastic Board is one of them.

03 Dec

- Vacuum Forming ABS Plastic Sheet is an emerging material in the sheet industry. Its full name is acrylonitrile/butadiene/styrene copolymer sheet, and it is the most widely used polymer with the larges...

14 Jul

- What is Smooth ABS Plastic Sheet?Smooth ABS Plastic Sheet is an emerging material in the sheet industry, its full name is Acrylonitrile/Butadiene/Styrene copolymer sheet, which is the most produced an...

23 Jun

- Properties: ABS Plastic Board has the appearance of opaque ivory-colored granules, non-toxic and tasteless, very low water absorption, can be made into a variety of colors, and has a 90% high gloss. a...

26 May

- Vacuum Forming ABS Plastic Sheet is a new material in the sheet industry and is the highest power polymer used and the most widely used polymer. The various functions of PS, SAN and BS are organically...

20 May

- Smooth ABS Plastic Sheet is an emerging material in the sheet industry. Its full name is acrylonitrile/butadiene/styrene copolymer sheet, and it is the most widely used polymer with the largest produc...

10 May

中文版

中文版

86

86

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888