How is hollow board processed?

May 09, 2021|

May 09, 2021| View:822

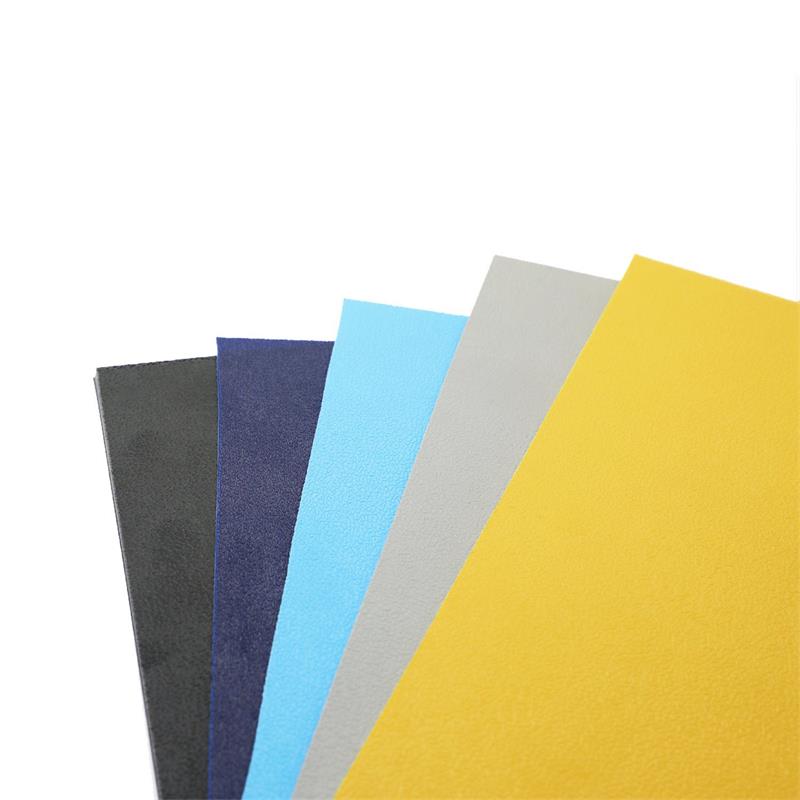

View:822Compared with paperboard structure products, hollow board has the advantages of moisture-proof and corrosion resistance, so hollow board is widely used in packaging, logistics and other fields, so how to produce hollow board?

1. If the moisture content of the raw material is more than 0.4%, it should be dried and baked for 1.5h in a constant temperature oven at about 100 ℃. The drying time is not easy to be too long to prevent the discoloration and decomposition of particles.

2. The barrel temperature is generally controlled at about 180 ℃. Even in the processing temperature range, the temperature should not be too high, let alone too long at high temperature, otherwise it is easy to cause degradation and affect product quality. The nozzle temperature is about 170%.

3. The mold temperature is controlled at about 50 ℃. The mold temperature of thin-walled and complex hollow plate should be higher. In order to reduce the stress of the hollow plate, the temperature difference of each part of the die should not exceed 5 ℃. Due to the low thermal deformation temperature of PVC, in order to prevent the demoulding deformation of hollow board and shorten the molding cycle, the mold needs to be cooled by water.

4. The injection pressure should be more than 90 MPa; The packing pressure is 70 MPa. Higher injection pressure is beneficial to the filling of molten material. The hollow plate is compact and has small shrinkage deformation after molding, but it brings some difficulties to the demoulding of hollow plate

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888