Take you to understand the difference between GPPS and HIPS Sheet

Mar 02, 2023|

Mar 02, 2023| View:403

View:403Polystyrene (PS) is one of the world's most popular thermoplastic materials, but depending on your application, you will need to use either HIPS Sheet or GPPS Sheet. each has unique properties that should be considered before deciding which one is best for your project and end user. This article will take you through the differences between GPPS and HIPS Sheet in detail.

1. What do GPPS and HIPS Sheet have in common?

While there are some key differences between HIPS Sheet and GPPS Sheet, they do share several common properties. Both are low-cost, rigid and easy to process and manufacture resins. These processing methods include injection molding, extrusion, blow molding and thermoforming.

Both GPPS and HIPS Sheet are FDA compliant, making them very common in kitchenware and food packaging applications. These are not the only application categories they share, as they can also be used in healthcare and housewares applications.

These polystyrene resins offer excellent aesthetics, good gloss, and are easy to paint, glue and print. GPPS and HIPS Sheet also each have Underwriters Laboratories approved 94HB and are recyclable.

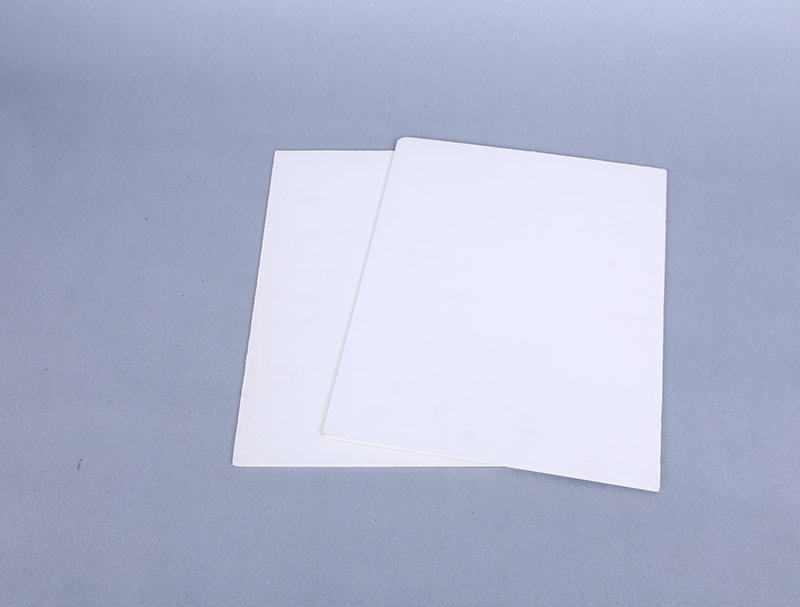

2. What are the unique qualities of HIPS Sheet?

HIPS Sheet is a polystyrene resin used in low heat applications. As the name implies, HIPS Sheet has high impact strength and good dimensional stability. HIPS Sheet is easy to thermoform and can be printed with digital, screen, flexographic and lithographic inks.

HIPS Sheet is naturally white with a matte finish, and although it is not naturally clear, HIPS Sheet can be easily painted and glued for excellent aesthetics. a good example of HIPS food packaging is yogurt cups.

Several HIPS Sheet grades are designed to have excellent resistance to specific end uses, such as refrigeration liners, toilet flaps and tanks, or disposables that require high environmental stress cracking.

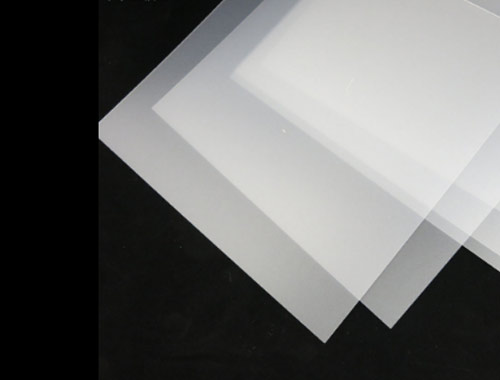

3. What are the unique qualities of GPPS Sheet?

While both GPPS and HIPS Sheet are considered low-cost, GPPS Sheet is the more cost-effective of the two polystyrene types. GPPS Sheet is brittle and has low impact strength as well as lower dimensional stability than HIPS Sheet.

Like HIPS Sheet, GPPS Sheet has a slight blue edge or water-clear edge tint. GPPS Sheet has a glass-like clarity that makes it popular in clear food packaging and can be easily molded into different shapes. Because of this, GPPS Sheet is also a popular choice for plastic toy applications.

GPPS Sheet is also commonly used in refrigerator trays, boxes, cosmetic packaging and CD cases.

Above is the difference between GPPS and HIPS Sheet. If you need more detailed information, please feel free to contact us!

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888