What are the main uses of ABS plastic sheet? How to evaluate?

Mar 10, 2021|

Mar 10, 2021| View:652

View:652What are the main uses of ABS plastic sheet? How to evaluate?

ABS plastic board is used for all kinds of small electrical appliances, small toys, car exterior. For how to distinguish, some abrasives in the whole process of manufacturing are printed with commodity materials, which can be seen from the plastic. Sometimes you can burn it with a lighter. When the ABS plastic plate is lit, it will turn out a lot of small bubbles at the ignition. It smells of a fragrance, and it can not describe it.

introduction

What is ABS plastic resin? ABS plastic resin is a kind of "acrylonitrile butadiene butadiene resin" (ABS resin), which is a ternary prepolymer of acrylonitrile (a), butadiene (b) and butadiene (s). It has strong, hard, good stiffness and other balanced comprehensive properties. It is a kind of general engineering project with large amount of commodities. Thermosetting plastic is one of the key types of butadiene resin.

ABS resin is made from three kinds of single butadiene, acrylonitrile and butadiene, which are made from polymer processing technology, such as moisturizing emulsion grafting, moisturizing emulsion grafted compound fertilizer or their own methods, which are amorphous, not transparent, and three yuan prepolymer. They are generally divided into various kinds of preservatives. Bead resin.

characteristic

ABS plastic plate is a kind of three-component polymer, which has the structure of two-phase asymmetry system of the graft prepolymer with polyurethane elastomer and the graft prepolymer with resin leading chain. This makes it have the properties of high aspect ratio organic chemical reliability, wear resistance and surface strength of acrylonitrile, ductility and cold resistance of butadiene, excellent dielectric polarity, gloss and process performance of butadiene. The particle size and spread of vulcanized rubber play a key role in the physical properties of ABS resin. The small particle vulcanized rubber can improve the gloss of crafts, and the large-size vulcanized rubber can improve the ductility of the resin, but the worse the gloss. The content is the key factor to determine the physical properties of resin. The content of raw materials increases, but the processing performance is reduced.

ABS resin is an amorphous polymer, without significant melting point, melting temperature of 221-245 ℃, decomposition reaction temperature of 270 ℃, non-toxic, odorless, high temperature and impact resistance. It has good ultra-low temperature impact resistance, specification reliability, electrical performance, wear resistance, molding process performance and mechanical equipment process performance; it is weak in aging resistance; flammable and light yellow when ignited, with exhaust exhaust The gas pipe has black smoke, which has unique odor, but does not drop; the thermal expansion temperature is low; the linear expansion coefficient is small, the molding shrinkage is small; it is easy to color, and has excellent solubility with the optical resin.

The heat resistance of ABS resin is good, but when the molding temperature is over 250 ℃, the vulcanized rubber in the resin tends to be destroyed and its properties are decreased. The viscosity of ABS resin is moderate, and its fluidity is lower than that of GPPS and polyester, but it is higher than PVC and PC, and the cooling dry solid rate of ABS resin is fast. The liquid circulation of the solution can be improved by raising the temperature of the barrel and the working pressure of the forming.

Molecular formula

ABS resin can produce specifications and models of commodities according to changing three kinds of single proportion and different polymer methods. The structure of ABS resin is graft prepolymer with polyurethane elastomer leading chain and graft prepolymer with resin leading chain. The general J species' single proportion category is about 25% ~ 30% of acrylonitrile, 25% ~ 30% butadiene and 40% ~ 50% butadiene. ABS resin is light yellow granular or bead resin, melting temperature is 217-237 ℃, decomposition reaction temperature is about 25o ℃, non-toxic, odorless and low moisture content. It has high-quality comprehensive physical-structural mechanical properties, excellent ultra-low temperature impact resistance, specification reliability, electrical performance, wear resistance, chemical resistance and dyeing property. Forming, processing and mechanical addition The manufacturing is good. ABS resin is resistant to moisture, carbonate, alkali and acid, does not dissolve most aldehydes and hydrocarbon solvents, but it is very easy to dissolve aldehydes, ketones, esters and some chlorohydrocarbons. The thermal expansion temperature of ABS resin is low, not completely transparent, flammable and aging resistant.

ABS resin can be mixed with a variety of resins to blends, such as PC / ABS, ABS / PVC, PA / ABS, PBT / ABS, etc., which results in new properties and new main uses, such as: mixing ABS resin and PMMA can produce and manufacture transparent ABS resin.

The key defects of ABS plastic board are: not completely transparent, not weather embrittlement and poor flame retardant performance. The flame retardant grade can be improved according to the addition of halogen-free flame retardant or blending with PVC, but the process performance is reduced. ABS is widely used to make machine equipment casings (such as telephone, TV and electronic computer), and this defect is set by default.

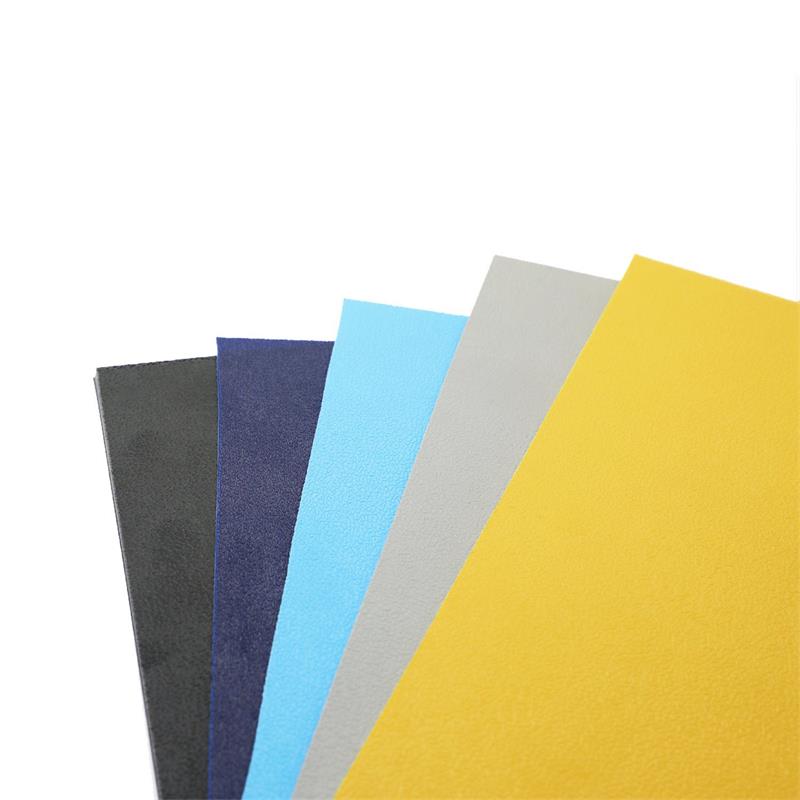

ABS plastic board ABS classification

ABS plastic board can be divided into: extremely tear resistant, high impact resistant, medium tear resistant, etc. according to the difference of molding process, ABS can be divided into: injection, extrusion, injection molding, vacuum pump, injection molding, etc; ABS can also be divided into general purpose, high temperature resistance, electroplating process, flame retardant, transparent, antistatic, extrusion plate and pipe fittings, etc.

Future outlook of ABS plastic sheet raw materials

ABS is a general thermosetting plastic engineering project plastic which is developing in the 21st century and is a kind of plastic with excellent mechanical properties of comprehensive structure. It not only has excellent rigidity, strength and production and processing circulation, but also has high wear resistance, and can be molded, extruded or hot formed. Most auto parts are produced and processed by injection molding. ABS resin has the advantages of tear resistance, noise reduction and sound insulation, scratch resistance, better temperature resistance, more beautiful and generous than PP, and it is very cross the components with strict tear resistance and application temperature.

ABS resin is the third largest resin which only uses polyurethane and polypropylene in the car. ABS resin can be used as the small components of the car and the exterior casing, steering wheel, oil guide pipe, door handle and key, etc. the outside of the vehicle includes front heat pipe radiator grille and lamp cover. ABS resin is very easy to produce and process, and the production specification reliability and surface gloss are good, so it is very easy to spray and color. It can carry out secondary production and processing performance such as painting metal materials, electroplating process, welding and bonding. It can be widely used in electronic and electrical industry, including various office and consumer electronic devices / household appliances. Office household appliances include various office and consumer electronics / household appliances Electronic device data processing method machine, office machine and equipment of the company. In recent years, in the electronic and electrical sales market, ABS resin will maintain its influence in the regulated fire-retardant and high temperature resistant electronic device / household electrical appliance sales market. The ABS resin with flame retardant and high temperature resistance has remarkable advantages in the market competition with the abs/pc and other engineering projects.

ABS resin has been widely used in daily necessities industry, such as decorative building materials pipe fittings, boards or plastic plates. In recent years, PVC resin with cheaper price has replaced a part. ABS resin is used as the industry related to engineering construction, in which extruded plastic sheet is used as environmental sanitation equipment such as bath box, swimming hall lining, etc., in addition, injection molding pipe fittings and pipes, and small amount of extruded telephone cable pipes are manufactured.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888