What raw materials are used for ABS composite board? Plastic or resin?

Mar 08, 2021|

Mar 08, 2021| View:672

View:672What raw materials are used in ABS composite board? Plastic or resin?

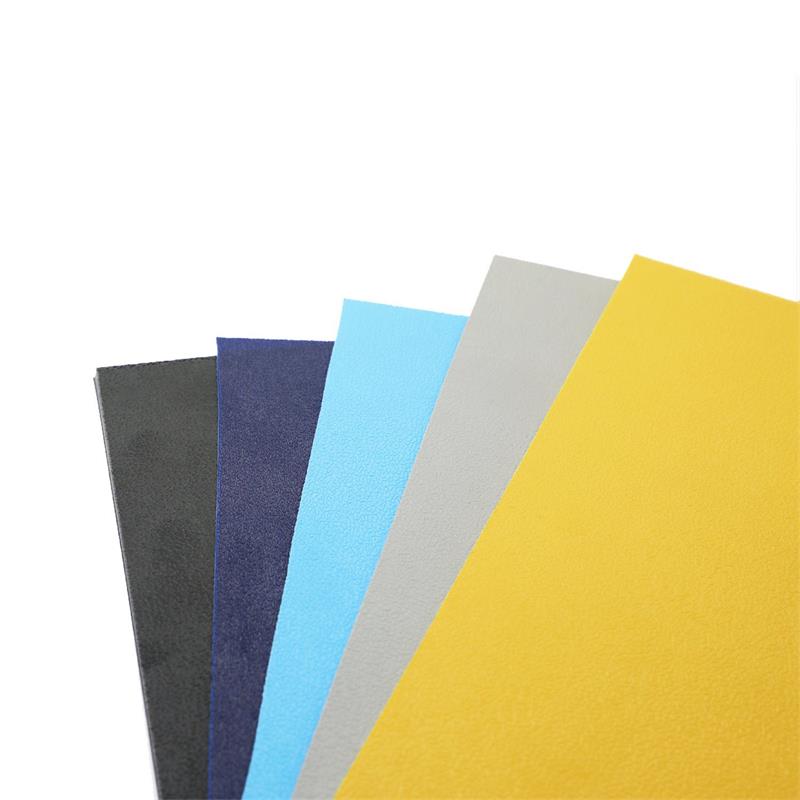

The raw materials used in ABS composite board can be divided into ABS resin and ABS plastic.

Among them, ABS plastic is the product of ABS resin. ABS resin is composed of acrylonitrile (Pan), butadiene (PB), butadiene (PS) three single mixture, the English name is acrylonitrile butadiene styrene, commonly known as ABS. ABS plastic is a kind of engineering project plastic after modified material (adding preservative or aluminum alloy) to improve the properties of ABS resin.

In the production of petrochemical equipment, the key to ABS composite board is to produce butadiene and acrylonitrile into AS resin according to the moisturizing emulsion method. Then the ABS resin is obtained from butadiene polymer in the condition of moisturizing emulsion.

The transparent ABS produced by MMA instead of acrylonitrile an, the high temperature resistant ABS obtained by PMI or MAH grafting ABS resin, and the flame retardant ABS obtained by halogen-free flame retardant all belong to ABS plastics.

In addition, there is also a name, resin is divided into natural resin and synthetic resin, in which synthetic resin can be called plastic. That is to say, ABS made of three single mixtures can be called ABS resin or ABS plastic.

Originally, the difference between resin and plastic is not very strict. Therefore, in the specific production or international business, whether the raw material of ABS composite board is plastic or resin is not the key.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888