ABS, PC / ABS alloy knowledge

Feb 25, 2021|

Feb 25, 2021| View:710

View:710ABS and PC / ABS alloy knowledge

01. Acrylonitrile butadiene styrene (ABS) is a kind of general thermoplastic engineering plastics. Its specific properties are as follows:

General performance

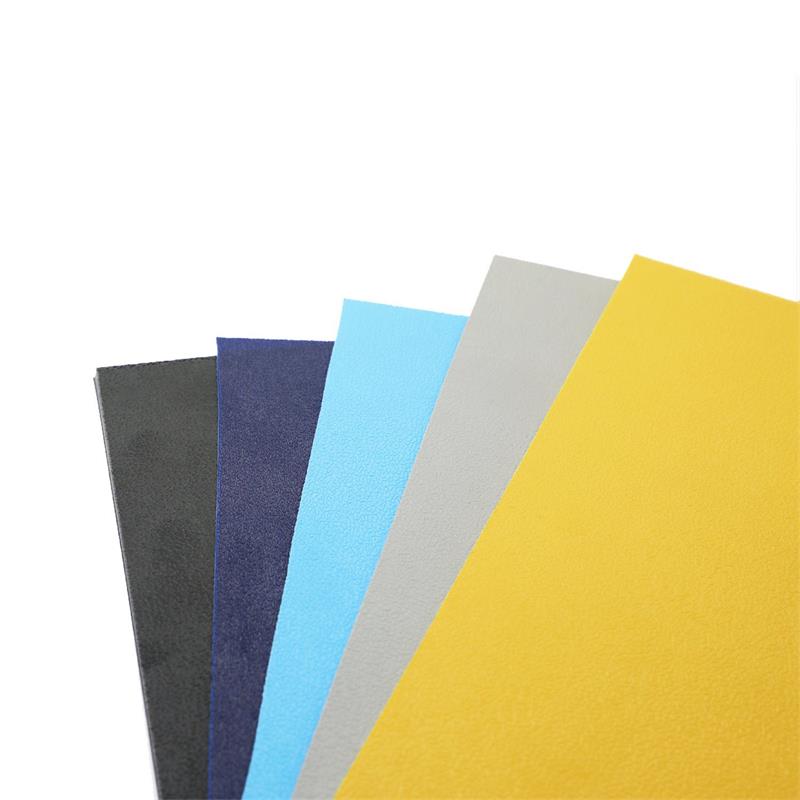

The appearance of ABS engineering plastics is opaque and ivory. Its products can be made into colorful materials with high gloss. The relative density of ABS is about 1.05, and the water absorption is low. ABS has good adhesion with other materials and is easy to be printed, coated and plated. The limiting oxygen index (LOI) of ABS is 18% ~ 20%. It is a flammable polymer with yellow flame, black smoke and special cinnamon flavor.

mechanical property

ABS has excellent mechanical properties, excellent impact strength, and can be used at extremely low temperature: ABS has excellent wear resistance, good dimensional stability, and oil resistance, and can be used for bearings under medium load and rotating speed. The creep resistance of ABS is larger than that of PSF and PC, but smaller than that of PA and POM. The bending strength and compressive strength of ABS are poor among the plastics. The mechanical properties of ABS are greatly affected by temperature.

Thermal Properties

The hot deformation temperature of ABS is 93 ~ 118 ℃, and the product can be increased by about 10 ℃ after annealing. ABS can still show certain toughness at - 40 ℃, and can be used in the temperature range of - 40 ~ 100 ℃.

Electrical performance

ABS has good electrical insulation, and is hardly affected by temperature, humidity and frequency. It can be used in most environments.

Environmental performance

ABS is not affected by water, inorganic salt, alkali and many kinds of acids, but it is soluble in ketones, aldehydes and chlorinated hydrocarbons. It will produce stress cracking when corroded by glacial acetic acid and vegetable oil. ABS has poor weatherability and is easy to degrade under the action of ultraviolet light. After six months outdoors, the impact strength of ABS is reduced by half.

Application of ABS resin

The most important application fields of ABS resin are automobile, electronics and building materials. The use of automobile field includes many parts, such as automobile instrument panel, body outer panel, interior trim panel, steering wheel, sound insulation panel, door lock, bumper, ventilation pipe and so on. In terms of electrical appliances, it is widely used in refrigerators, TV sets, washing machines, air conditioners, computers, copiers and other electronic appliances. Building materials, ABS pipes, ABS sanitary ware, ABS decorative panels. In addition, ABS is widely used in packaging, furniture, sporting goods and entertainment goods, machinery and instruments in industry.

The important indicators of automotive interior include beauty, low odor, good mechanical properties, heat resistance, weather resistance, etc. Automotive materials can meet the use requirements of various interior parts, materials have the following conditions: good liquidity; excellent impact resistance; easy processing and molding; easy coloring and spraying; low odor; good corrosion resistance; matt effect. ABS is also used in 3D printing.

02. PC / ABS alloy

In order to overcome the above shortcomings of ABS, PC / ABS alloy is prepared by blending polycarbonate (PC) with ABS. Usually, the mass ratio of PC / ABS is 70 / 30. This ratio is a comprehensive consideration of the thickness, temperature and other factors on the impact properties. The alloy combines the formability of ABS material with the mechanical properties, impact strength, temperature resistance and ultraviolet resistance of PC. It can be widely used in automotive internal parts, various machines, communication equipment, household appliances and lighting equipment.

Automobile interior and exterior decoration: instrument panel, pillar, front cover, grille, interior and exterior decoration

Business equipment case and built-in parts: Notebook / desktop computer, copier, printer, plotter, monitor

Telecom, mobile phone case, accessories and smart card (SIM card).

Electrical products: electronic products shell, meter cover and shell, household switch, plug and socket, cable and conduit

Household appliances: washing machine, hair dryer, microwave oven, internal and external parts

The process conditions of PC / ABS injection mold are as follows

Drying must be done before processing. The humidity should be less than 0.04%, and the recommended drying condition is 90 ~ 110 ℃ for 2 ~ 4H;

The melting temperature is 230 ~ 300 ℃;

Mold temperature: 50 ~ 100 ℃.

The injection pressure depends on the plastic part.

The injection speed should be as high as possible.

Chemical and physical properties: PC / ABS has the comprehensive properties of PC and ABS. For example, ABS easy processing characteristics and PC excellent mechanical properties and thermal stability. The ratio of the two will affect the thermal stability of PC / ABS. PC / ABS Blends also show excellent fluidity. The shrinkage is about 0.5%.

03. Problems and solutions of injection molding PC / ABS products

Silver wire problem

Silver wire is the most common problem of PC / ABS materials. Silver wire, also known as craze, water spray and material flower, is the phenomenon of silver white filiform stripes on the surface of products along the flow direction.

The main reason is the interference of gas, which is mainly divided into three components: air: melt glue and air involved in the injection stage; water: water contained in the material itself; cracking gas: gas produced by high temperature hydrolysis / thermal decomposition.

Solution: first check whether the material is dry enough. After confirming that the material is dry enough, adjust the injection molding process to improve the silver wire defects. At the same time, poor injection silver wire is also related to mold exhaust.

Flow mark problem

The flow mark is produced when the material is injected. The reason is that the material has poor fluidity. The flow mark is different from the craze and has different appearance.

Solution: it can be avoided by increasing the temperature of the material to improve the fluidity, properly improving the fluidity of the material in the mold and reducing the injection speed.

Shrinkage and dent problems

Shrinkage is caused by insufficient filling of material in the cavity.

The solution: properly increase the mold temperature and material temperature to improve the material fluidity, extend the injection holding time, increase the injection pressure, increase the injection speed to improve the mold filling performance, also can increase the size of the gate, heat the gate runner to reduce and eliminate product shrinkage;

Dents are caused by improper material temperature and improper product design. When the material temperature is too low, not only shrinkage will occur, but also dents will occur. When the material temperature is too high and the mold temperature is too high, the molten material will shrink excessively during cooling, resulting in dents.

Warpage problem

The warpage of injection molded parts is caused by unreasonable design, improper gate position and unreasonable injection processing conditions, resulting in internal stress, uneven or excessive shrinkage. The mold temperature is too high or uneven, which leads to difficult demoulding of injection molded parts, or uneven cooling, which also leads to warpage;

resolvent:

Processing technology: lengthen the injection molding cycle, reduce the injection temperature, adjust the injection pressure and injection speed properly, reduce the ejection speed, increase the ejection area, and maintain the balance of ejection force;

Product design: increase the wall thickness, add stiffeners and corner reinforcement;

Speckle problem

It is usually due to the "melt fracture" caused by the expansion of the melt into the mold cavity during high-speed injection.

resolvent:

Molding process: to increase the material temperature, nozzle temperature, slow down the injection speed, etc. to reduce the appearance of speckle;

Mold: increase mold temperature, add overflow groove, increase gate size, modify gate shape.

Pitting problem

Solution: poor dispersion, add dispersant or oil, increase temperature, add back pressure. And see if it's a mold problem. Use other materials.

Whether the baking temperature and time are enough. Adjust the mold temperature properly.

Peeling of products

The peeling problem of plastic products is closely related to the fracture of fluid caused by high shear force. At low shear stress or rate, the small disturbance caused by various factors is restrained by melt. At high shear stress or rate, the disturbance in fluid is difficult to be restrained and develops into unstable flow. When a critical shear force is reached, the fracture of fluid will be caused.

resolvent:

Material aspect: because the bad peeling caused by the mixture needs to be eliminated in step (DI), the PC and ABS are partially compatible, so it is necessary to add appropriate compatibilizer in the modification process to improve its compatibility;

Mold: the principle of mold design should follow the direction of cutting as much as possible. Generally speaking, the products with dense dermatoglyphic surface are more prone to peeling (caused by the friction and shear between the melt in the cavity and the inner wall of the cavity during high-speed filling); at the same time, in the design of the gate, if the gate size is too small, it will lead to excessive shear when the melt passes through the gate, and then lead to peeling on the product surface;

Injection molding process: the main direction is to avoid excessive shear. When the product is difficult to fill, it can be improved by high speed and high pressure. Therefore, in the actual injection process, we can also consider increasing the injection temperature / mold temperature and improving the material fluidity to reduce the flow resistance in the actual filling process, so as to avoid excessive shear caused by high speed and high pressure.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888