Characteristics of ABS plastic injection molding

Feb 19, 2021|

Feb 19, 2021| View:638

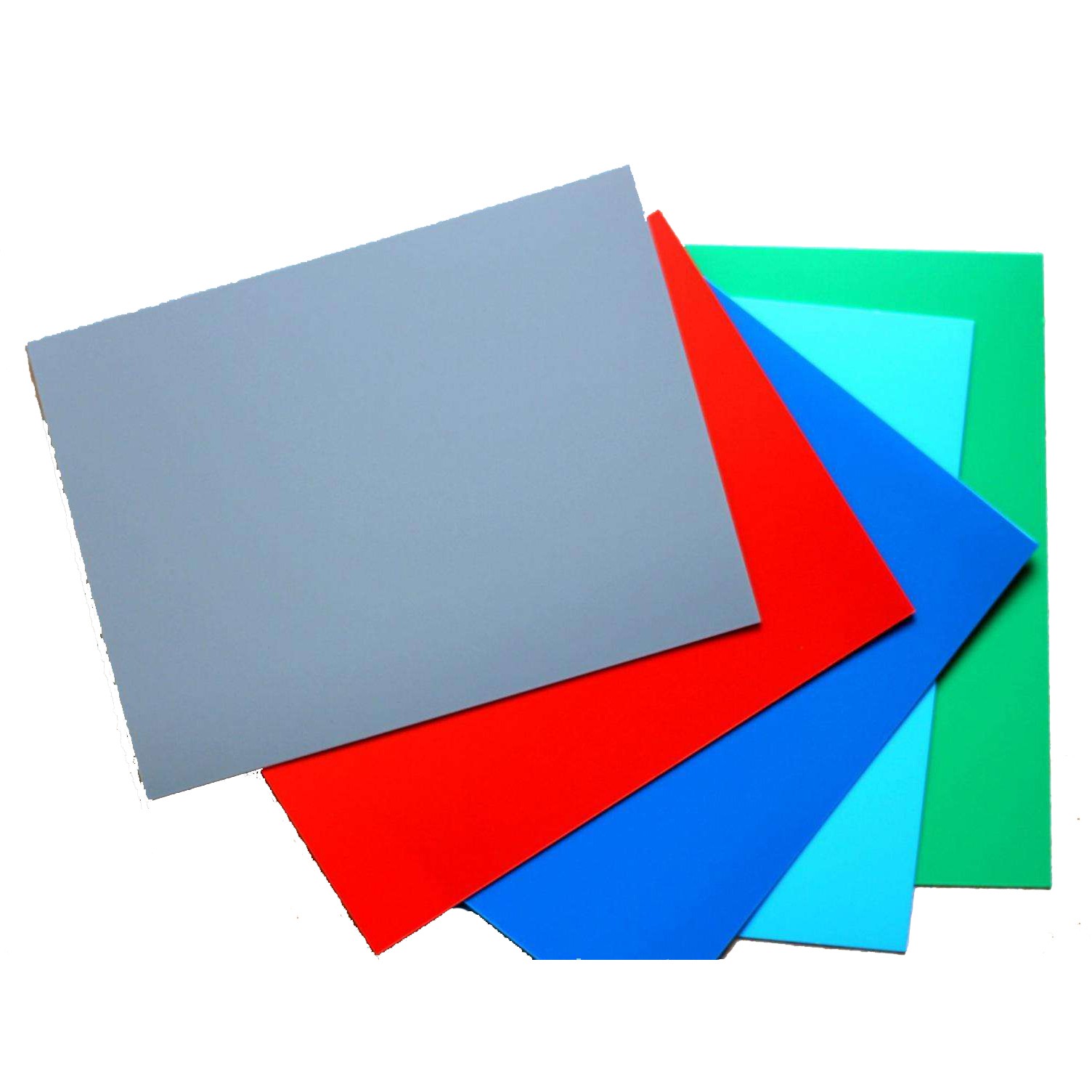

View:638ABS plastic is one of the five major synthetic resins: it has excellent impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical performance. It also has the characteristics of easy processing, stable product size, good surface gloss, easy painting and coloring. It can also carry out secondary processing such as surface plating, electroplating, welding, hot pressing and bonding. It is widely used in machinery, automobile and electronics Electrical appliances, instrumentation, textile and construction industries, is a very wide range of applications of thermoplastic engineering plastics. ABS plastic is usually light yellow or milky white granular non crystalline resin.

A、 ABS plastic physical characteristics:

1. It has good comprehensive properties, high impact strength, chemical stability and good electrical properties;

2. It has good fusibility with 372 plexiglass, can be made into two-color plastic parts, and the surface can be plated with chromium and sprayed with paint;

3. There are high impact, high heat resistance, flame retardant, reinforced, transparent and other levels;

4. The fluidity is worse than hips, better than PMMA, PC and so on, and the flexibility is good;

5. Suitable for making general mechanical parts, wear-resistant parts, transmission parts and telecommunication parts.

B、 ABS plastic molding features:

1. Amorphous material, medium fluidity, high moisture absorption, must be fully dried, the surface of the plastic parts required gloss must be preheated for a long time, drying 80-90 degrees, 3 hours;

2. High material temperature and high mold temperature should be adopted, but it is easy to decompose when the material temperature is too high (decomposition temperature is > 270 ℃). For high precision plastic parts, the mold temperature should be 50-60 ℃. For high gloss and heat resistant plastic parts, the mold temperature should be 60-80 ℃;

3. In order to solve the problem of water inclusion, it is necessary to improve the fluidity of the material, adopt high material temperature, high mold temperature, or change the water level;

4. For example, if heat-resistant or flame-retardant materials are formed, plastic decomposition products will remain on the mold surface after 3-7 days of production, which will cause the mold surface to shine. It is necessary to clean the mold in time, and at the same time, the exhaust position should be increased on the mold surface;

5. The cooling speed is fast, the mold pouring system should be based on the principle of thick and short, the cold material hole should be set, and the gate should be large, such as direct gate, disc gate or fan gate, but the increase of internal stress should be prevented, and the adjustable gate can be used when necessary. The mould should be heated and wear-resistant steel should be selected;

6. The material temperature has a great influence on the quality of plastic parts. Too low material temperature will cause lack of material, dull surface, disorder of silver wire, too high material temperature is easy to overflow, silver wire dark strip will appear, and plastic parts will change color and bubble;

7. Mold temperature has a great influence on the quality of plastic parts. When mold temperature is low, shrinkage, elongation, impact strength, bending strength, compressive strength and tensile strength are high. When the mold temperature exceeds 120 ℃, the plastic parts cool slowly, deform easily, stick to the mold, demould difficultly, and the molding cycle is long;

8. Forming shrinkage is small, easy to melt cracking, resulting in stress concentration, so the forming conditions should be strictly controlled during forming, and the plastic parts should be annealed after forming;

9. High melting temperature, high viscosity, not sensitive to shear. For plastic parts larger than 200g, screw type injection machine should be used, nozzle should be heated, open type extended nozzle should be used, and injection speed should be medium and high.

中文版

中文版

No. 323 Longjin Road Economic Development Zone Changzhou City

No. 323 Longjin Road Economic Development Zone Changzhou City 0086-519-81808688 0086-13327890888

0086-519-81808688 0086-13327890888